Well, setup two went pretty fast, so we’re gonna skip the “rolling” post and go right to the “it’s done” post.

This, is that.

Pictars here:

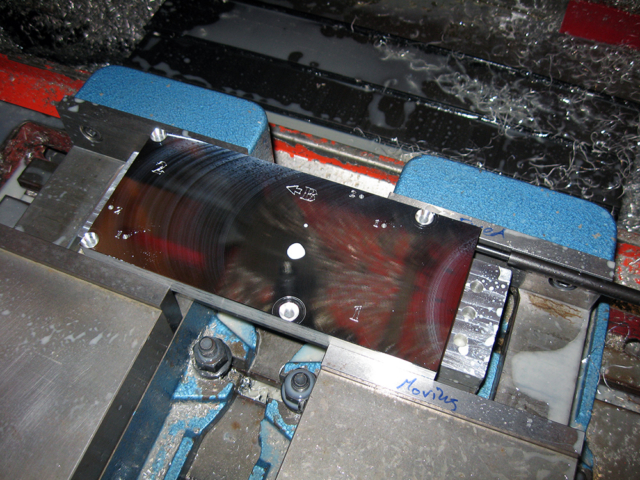

First couple are of the jig plate in the machine after the part has been ran through the second setup.

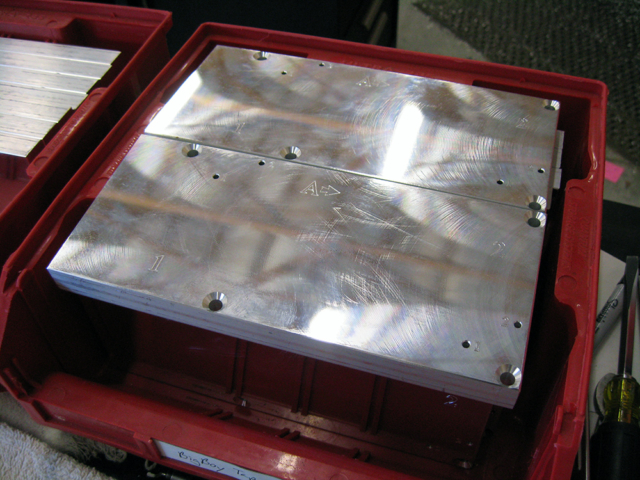

Next three are of various piles of parts from both before and after the second setup.

The last two are of the swarf levels inside the machine enclosure.

Pretty sure I’ma need to shovel out the enclosure before I run setup three on these parts.

It’s good though. Swarf means progress is being made.

On to programming and making the fixture plate for setup three (the last setup on these parts).

Thanks for hanging in there guys.

That is all.

im just curious what do you do with all those shavings? lol! Glad things are going smoothly!

I shovel them out of the enclosure into 55 gal drums and steel totes that I can stack outside until I’ve got a trailer load big enough to justify a trip to the scrap yard to recycle them.

Since they’re all one alloy of aluminum you get a pretty decent price for them (relatively speaking).

Even if the money they bring in is very small, it’s worth the effort just to not have totes and barrels (or big piles) of swarf everywhere.

Will you have any extras for sale? I pre ordered the tec 9 setup last year and have been itching for a new build. Being in quarantine hasnt helped lol. Tired of building glocks, 1911’s and AR’s. So If there are any extras please let me know and i love what you guys are doing keep up the amazing work

There are none left in the current batch, but there were enough people like yourself looking for a spare that I just went ahead and started a preorder for a new batch.

That can be found here: https://logic80.com/product/cs12-80preorder2/

I will start in on them as soon as the upcoming batch of Tec9 lowers are done.

Out of curiosity, if one was to order a cs12-80 on the pre-order, what’s the eta?

Current Estimate is Mid-Late Summer 2021

Can I ask how things are coming? Hope it’s all going smooth for you!

Still working on the jig plates.

Got a new machine in the shop, so things have been in an almighty uproar for the last two weeks.

Hope to have everything back together and working again by the end of this coming week.

Waiting on a new phase converter right now, but that should land sometime this coming week.

Big doings though. The lower jig plates will be the first parts run on the new machine.

Very excited, but had to move literally everything in the shop to fit the new VMC in place, so we’re pretty much down until I get it all put back together again. That’s what I’ve been working on for the last week or so.

thanks for the update!

Do you have a 3rd batch of cs1280 relievers coming up anytime soon? Or

Could you please tell me if you’re planning on building anymore of the CS 1280? Would love to get one if possible.